The energy costs in SWRO plants could represent up to 40 – 45% of the final costs of the water product, thus making highly efficient Energy Recovery Devices (ERD) of vital importance, as they allow for energy to be recovered from the brine stream.

There are mainly two types of ERDs available in market today.

- Energy Recovery Turbine (Pelton Turbine)

- Pressure Exchangers (Isobaric Devices)

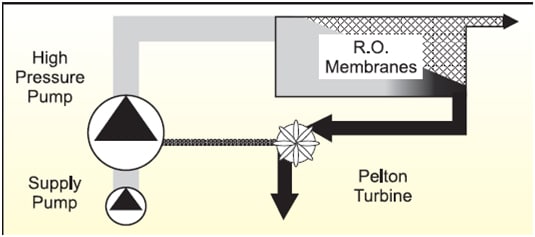

1. Energy Recovery Turbine:

A Pelton device is a tangential flow impulse turbine. Pressurised reject is ejected through one or more nozzles is directed against a

series of spoon-shaped buckets mounted around the edge of a wheel. Each bucket reverses the flow of water, leaving it with diminished energy and the resulting impulse spins the turbine.

The buckets are mounted in pairs to keep the forces on the wheel balanced as well as to ensure smooth, efficient momentum transfer of the fluid jet to the wheel. The wheel is mounted on the high-pressure pump shaft, which together with a motor drive the pump that pressurises the SWRO system.

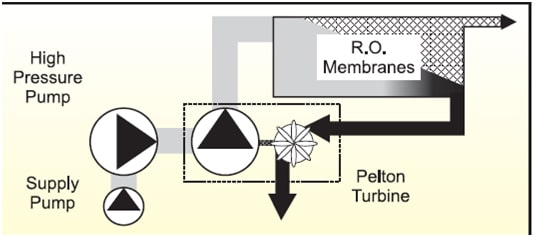

A modification of this is known as Hydraulic Turbo Charger. One or more nozzles direct the SWRO reject stream onto a tangential-flow pump turbine directly connected to a centrifugal impeller spinning in the SWRO feed stream. The feed stream, partially pressurised by a high-pressure pump, is boosted by the Turbocharger impeller to the SWRO feed pressure. The turbocharger and the high-pressure pump are not directly connected, providing a degree of flexibility in the operation of these devices. Also, turbochargers have a relatively small footprint and are easy to install. Currently Pump Engineering Inc.(PEI) & Fluid Equipment Development Company (FEDCO) manufacture this type of ERDs.

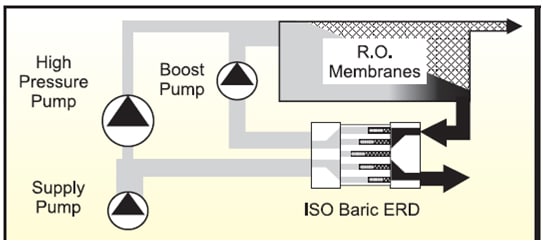

Pressure Exchangers:

To avoid the efficiency losses inherent to Mechanical to Pressure Energy conversion in centrifugal ERDs, the Positive displacement piston isobaric devices were developed in 80s. These devices transfer the reject pressure to low pressure feed in Equalising or Isobaric chambers. The Isobaric devices can recover up to 98% of energy in waste stream depending upon the system configuration & size.

The pressurised feed from ERD combines with discharge of HPP as feed to membranes. The HPP operates at full feed pressure but supplies only portion of total feed ~ 40% of total feed. A booster pump is needed in series with ERD to match feed pressure required for membranes.

As it can be seen in below sketch, the Isobaric devices completely decouple the ERD and the HPP. The advantage of this feature is that HPP size is not restricted by ERD size & pressure centre system SWRO can be designed. The larger HPP gives better efficiency coupled with efficiency of Isobaric device, further reducing power consumption.

Currently ERI, Flowserve, Kinetico & Grudfos make Isobaric devices under various trade names.

Following table compares major points of the Pelton Turbines to Isobaric Devices performance:urther down.

Criteria

| Pelton turbines | Isobaric ERDs

|

| Typical train capacity | Up to 5000 m3/d (Single Train) | More than 5000 m3/d |

| Typical recovery rate | 45 – 50% | 37 – 45% |

| HPP power For pumping | 100% feed water | 37 – 45%of total feed water |

| No. of booster pumpsrequired | n/a | 1 for each energyrecovery device |

| Relevant civil workrequirements | Yes | No |

| Salinity increase of thefeed water beforemembranes | No | Yes |

| Extra brine pipeinstallation | Yes | No |

| Flow leakages (lubrication) | n/a | Yes |

| Average efficiency | 80 to 90% | 90 – 98% |

| Typical SEC achieved | 3-4 kWh/m3 | 2- 3 kWh/m3 |

| Energy savings range(after installing) | 35 – 42% | 55 – 60% |

| Operating Range | Variation in flow > 10% will reduce efficiency. | Relatively bigger span of allowable flow range for same efficiency |

| Cost | Lower | Higher |

SEC: Specific Energy Consumption

n/a: not applicable.

The choice of specific type generally depends on the SWRO plant size, SWRO configuration, Site specific conditions, Project budget, Fuels’ costs in region etc.

There are new ERDs which are under development like Fluid Switcher (FS), Isobarix, Desalitech’s CCD etc. These developments coupled with Low Energy Membranes will bring the SWRO SEC further down.