MBBR is an improved version of Fixed Film Bio Reactor like SAFF (Surface Area Fixed Filmed Technology (SAFF) or Rotating Bio Reactor (RBC), with a difference of MBBR carrier media is free floating in the Sewage/Effluent. MBBR technology employs thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin.

A Moving Bed Biofilm MBBR reactor consists of a tank with submerged but floating plastic (usually HDPE, polyethylene or polypropylene) media having specific gravity less than 1.0. The large surface area of the plastics provide abundant surface for bacterial growth. Biomass grows on the surface as a thin film whose thickness usually varies between 50-300 microns. Each individual bio carrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. Medium or coarse bubble diffusers uniformly placed at the bottom of the reactor maintains a dissolved oxygen (DO) concentration of > 2.5-3 mg/L for BOD removal. Still higher DO concentrations are maintained for nitrification. To retain the media flowing out of the tank, screens are placed on the downstream walls. A clarifier or a DAF is placed downstream of the MBBR tank to separate the biomass and the solids from the wastewater. No sludge recycle is required for this process. A typical MBR Media is shown below.

For denitrification, anoxic Moving Bed Biofilm Reactor MBBR tanks are used. The anoxic tank is similar to aerobic Moving Bed Biofilm Reactor MBBR tank described above except that no oxygen is supplied. The tank contains no diffusers and the media is kept in suspension in the reactor through submersible mixers. Other feature such as the screen is the same as aerobic reactor although the design may be slightly different.

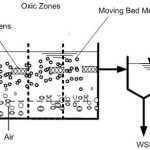

A schematic of the Moving Bed Biofilm Reactor MBBR process for BOD removal is shown below.

Wastewater enters the Moving Bed Biofilm Reactor MBBR where the biomass attached to the surface of the media degrades organic matter resulting in BOD removal and/or nitrification depending on the type and characteristic of the wastewater. Organic carbon is converted to carbon dioxide and leaves the system while the ammonia and nitrogen in the organics are converted to nitrates through nitrification process. Oxygen required for the process is provided through the diffusers installed at the bottom of the reactor. The treated wastewater then flows through the screens to the downstream clarifier where the biomass and solids are separated from the wastewater.

There are more than a thousand Moving Bed Biofilm Reactor MBBR installations worldwide. Moving Bed Biofilm Reactor technology can be used for wastewater treatment for the following industries: food and beverage plants, steel mills, oil refineries, petrochemicals, chemical plants, paper mills and any industries requiring wastewater treatment for BOD removal, nitrification and denitrification.

MBBR technology has become the preferred biological treatment technology because it offers several advantages over the traditional Activated Sludge Process, the most popular technology.

Some of the key features of MBBR process are provided below:

1. Robust – It is stable under load variations, insensitive to temporary limitation and provides consistent treatment results

2. Efficient – It generates low solids and requires no or minimum polymer for solid/liquid separation

3. Compact – It requires a small footprint. Typically it requires 1/3rd the space required for Activated Sludge Process.

4. Cost – It requires a low capital cost and is comparable to cost of Activated Sludge Process. It is cheaper than the MBR process.

5. Flexible – Existing plants can be upgraded easily with MBBR. New MBBR plants can be upgraded to handle higher loads with no or minimum cost and construction.

6. Trouble Free – It is easy to operate, has automatic sludge wasting, has no sludge Return and no MLSS, and there no issue of media clogging.

7. Expandable – Capacity can be easily upgraded by simply increasing the fill fraction of biofilm carriers

– Single Pass Process – No return activated sludge stream required

– Load Responsive – Actively sloughed biofilm automatically responds to load fluctuations

– Minimal Maintenance – No F/M ratios or MLSS levels to maintain.

MBBR processes are an excellent solution for common wastewater applications including:

– BOD Reduction

– Nitrification

– Total Nitrogen Removal

Moving Bed Biofilm Reactor systems deliver a flexible, cost-effective, and easy-to-operate means to address current wastewater requirements and the expandability to meet future loads or more stringent discharge requirements within a compact design.